Automazione Industriale

Disponibile

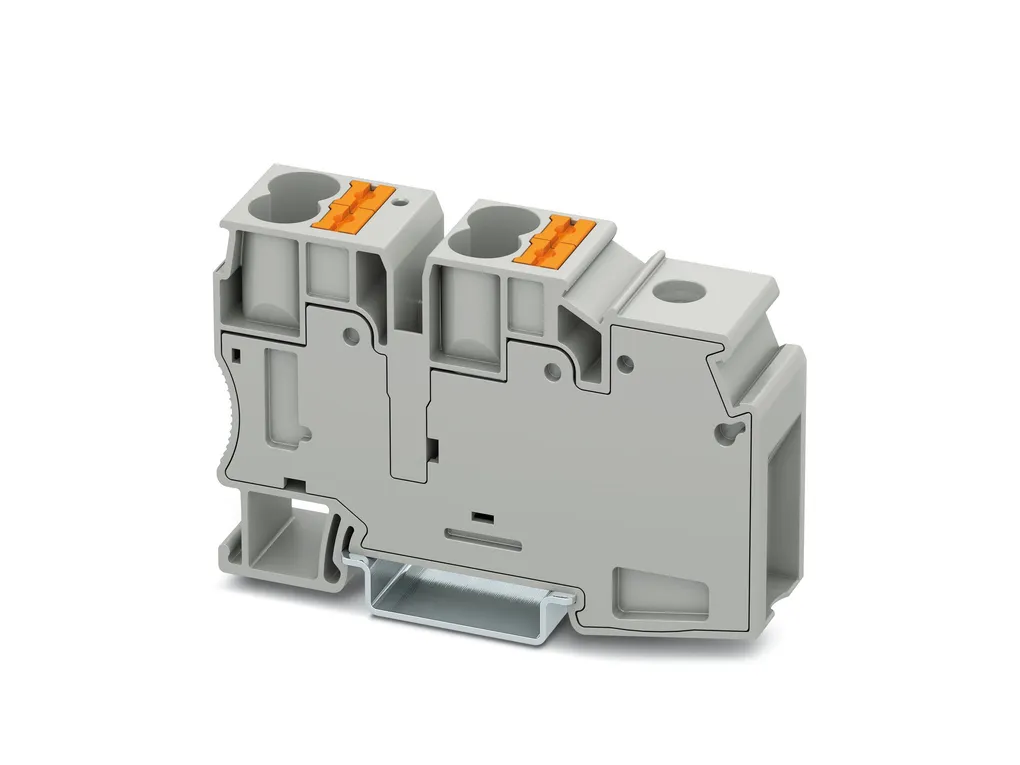

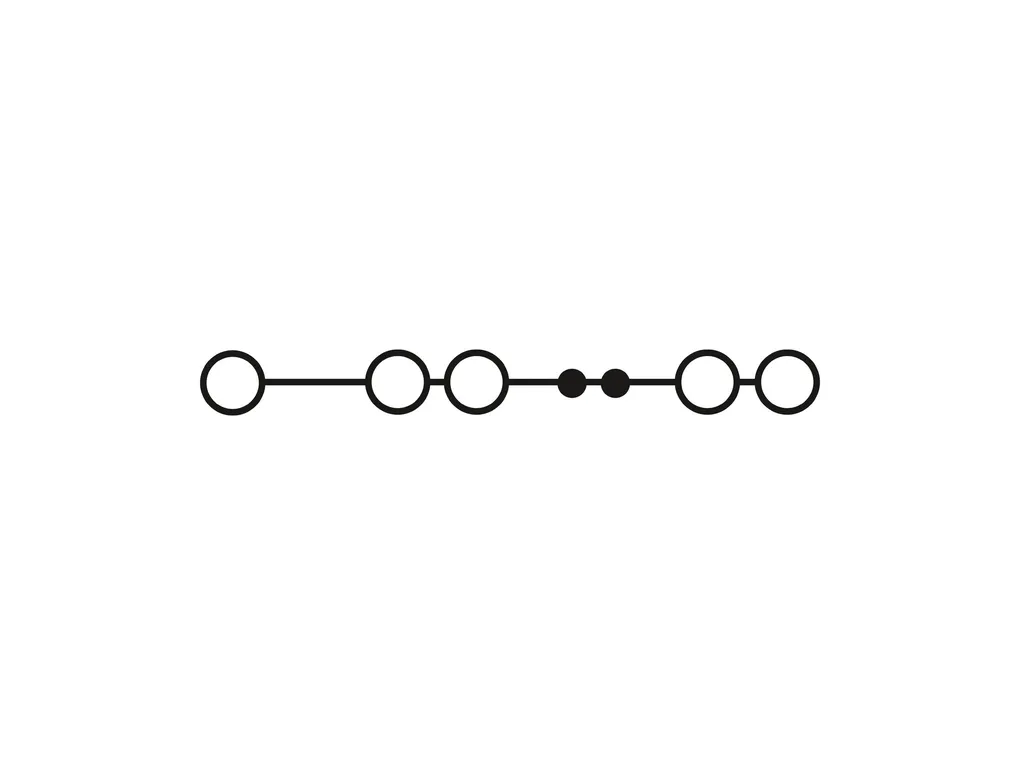

Disponibile PTU 35/4X10 - Potential collective terminal

Potential collective terminal, nom. voltage: 1000 V, nominal current: 101 A, number of connections: 5, connection method: Screw connection, Rated cross section: 35 mm2, cross section: 1.5 mm2-50 mm2, Push-in connection, Rated cross section: 10 mm2, cross section: 0.5 mm2-10 mm2, mounting type: NS 35/7,5, NS35/15, color: gray

Cod. Articolo: 3002371

Cod. Fornitore: 3002371

PHOENIX CONTACT