Automazione Industriale

Non disponibile

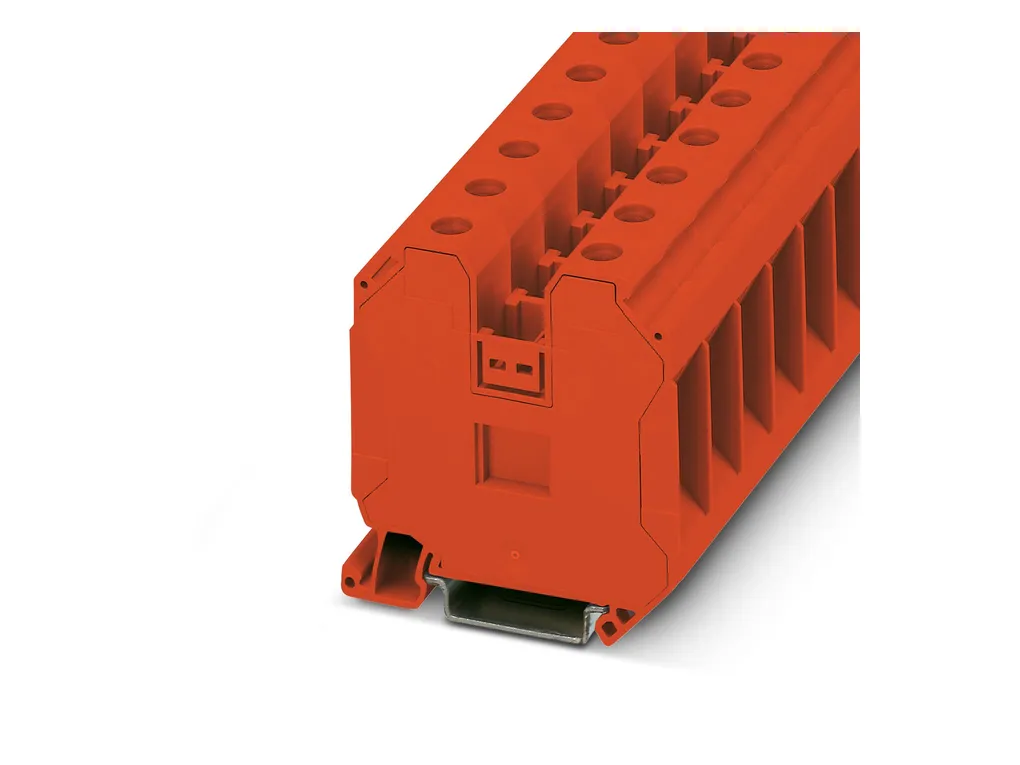

Non disponibile UDB 2X25/16 GY - Trunk line branch terminal

Trunk line branch terminal, nom. voltage: 400 V, nominal current: 101 A, number of connections: 4, number of positions: 1, connection method: Screw connection, 1 level, Rated cross section: 25 mm2, cross section: 1.5 mm2-25 mm2, Screw connection, 2nd level, cross section: 1.5 mm2-16 mm2, mounting type: NS 35/7,5, NS35/15, color: gray

Cod. Articolo: 3071355

Cod. Fornitore: 3071355

PHOENIX CONTACT