Automazione Industriale

Non disponibile

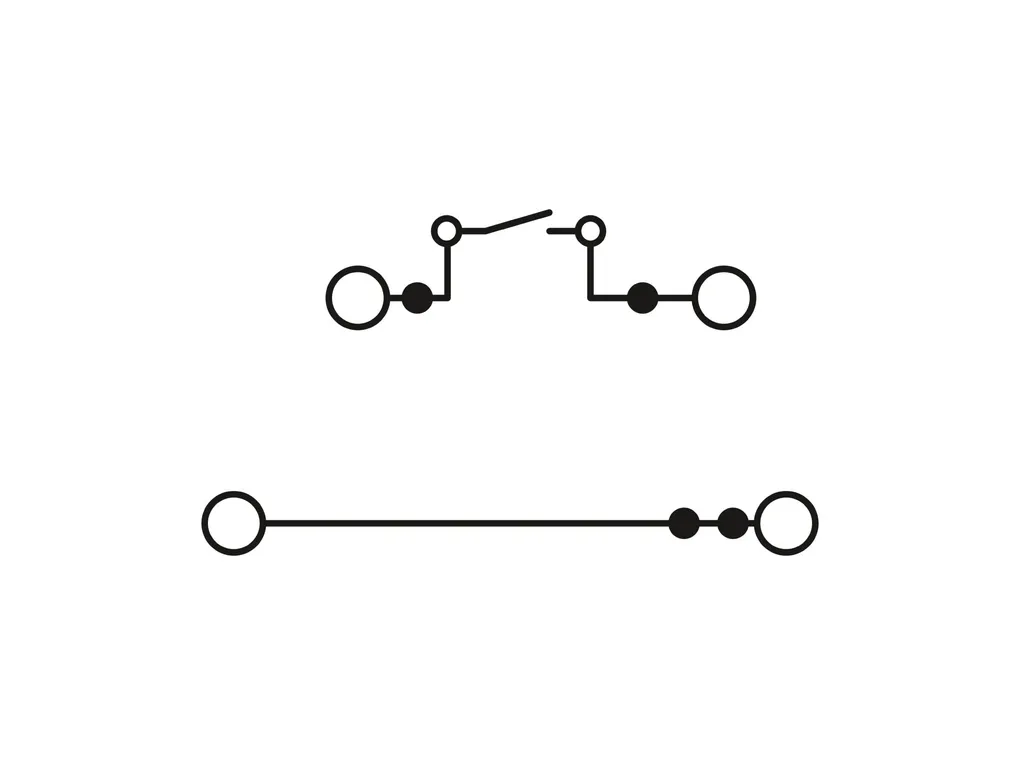

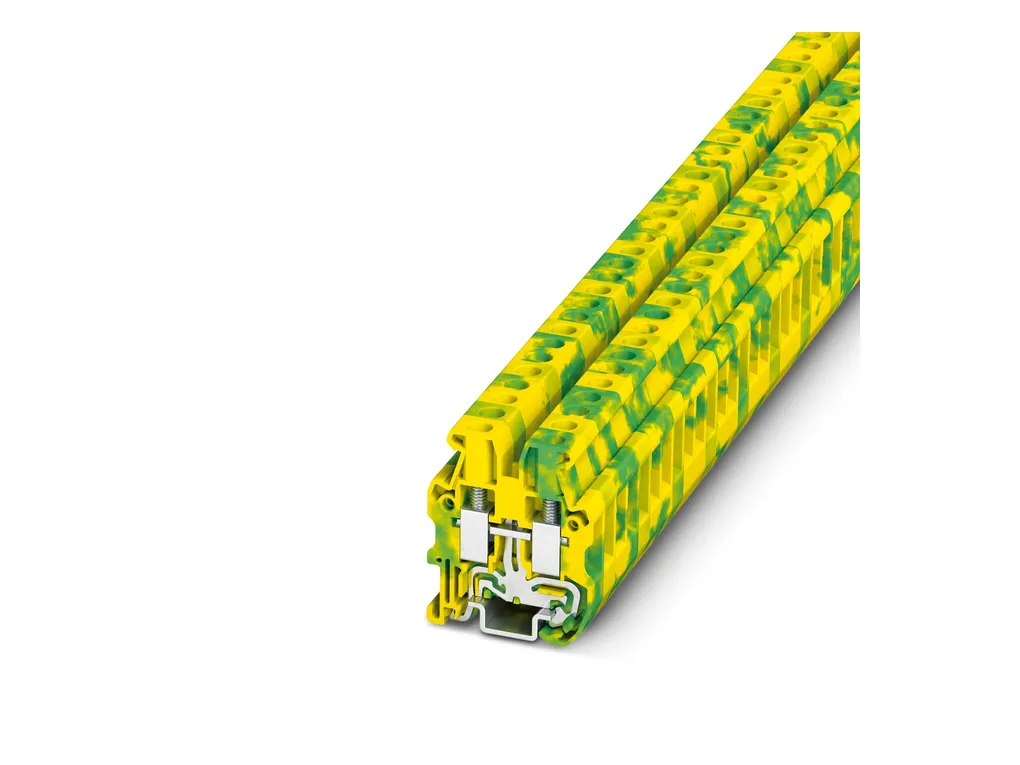

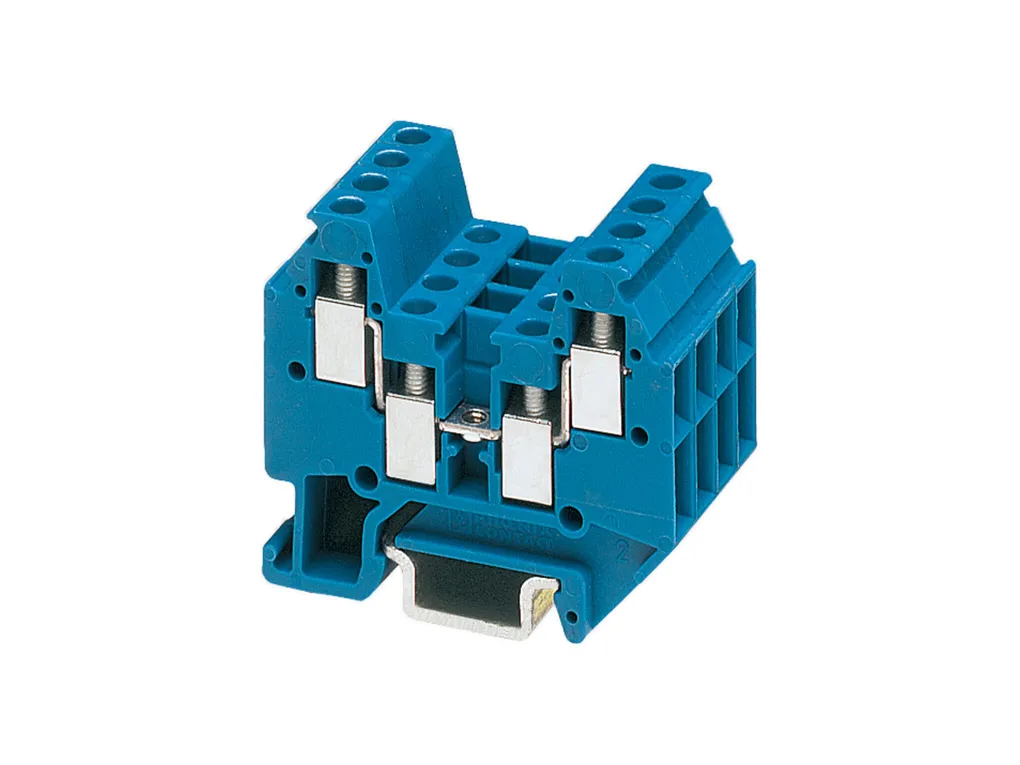

Non disponibile UTI 2,5-L/LTB - Installation level terminal block

Installation level terminal block, with integrated disconnect knife, nom. voltage: 400 V, nominal current: 24 A, Screw connection, 1st, 2nd and 3rd level, Rated cross section: 4 mm2, cross section: 0.2 mm2 - 4 mm2, Rated cross section: 1.5 mm2, mounting type: NS 35/7,5, NS 35/15, color: gray

Cod. Articolo: 3076023

Cod. Fornitore: 3076023

PHOENIX CONTACT