Automazione Industriale

Disponibile

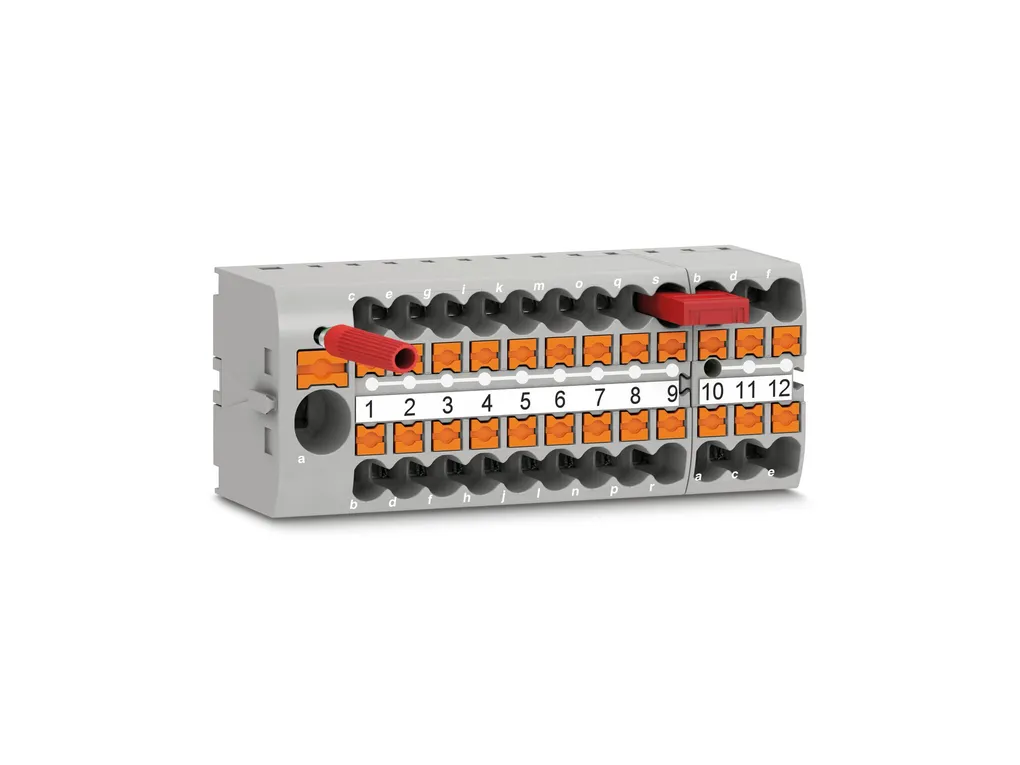

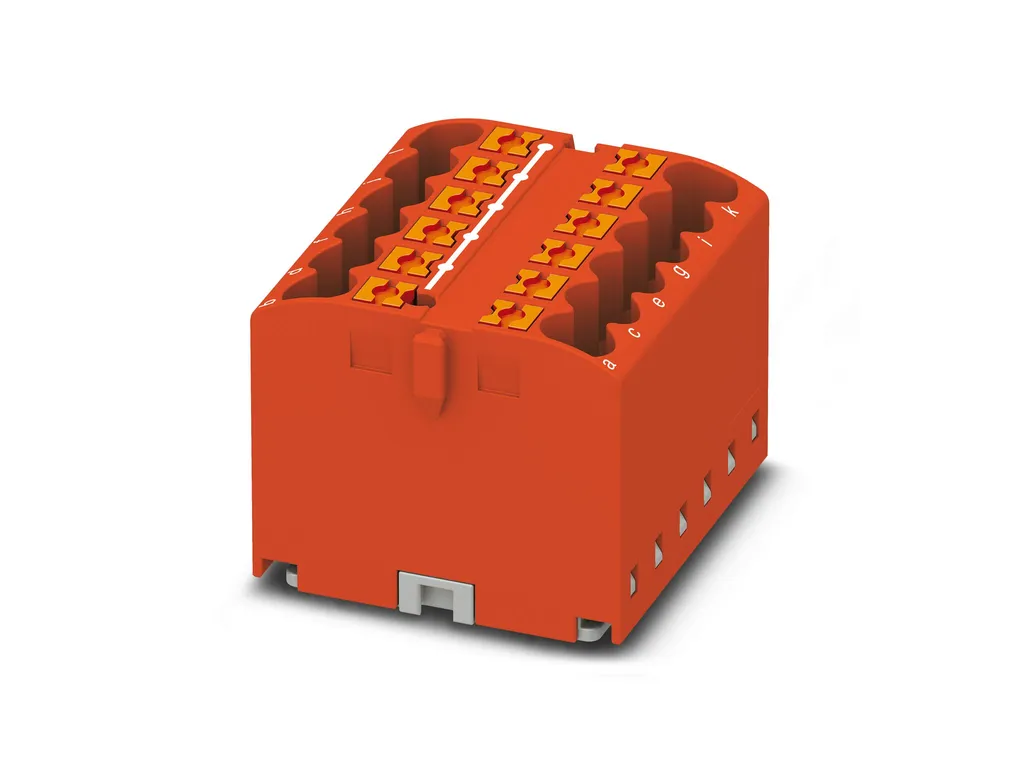

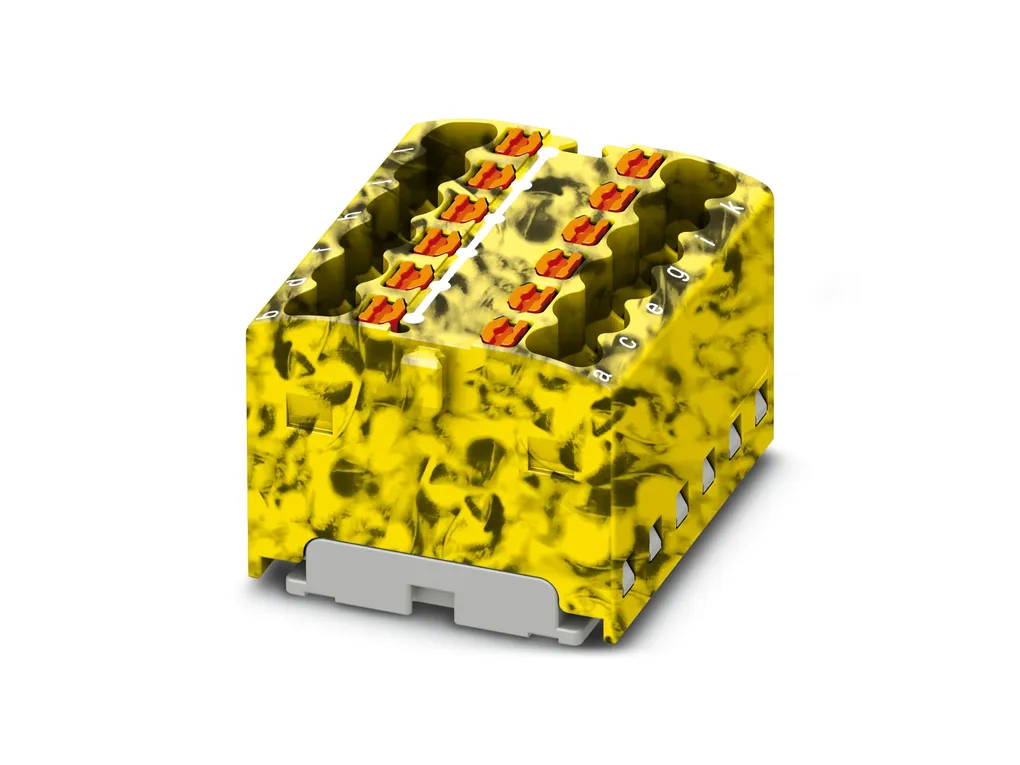

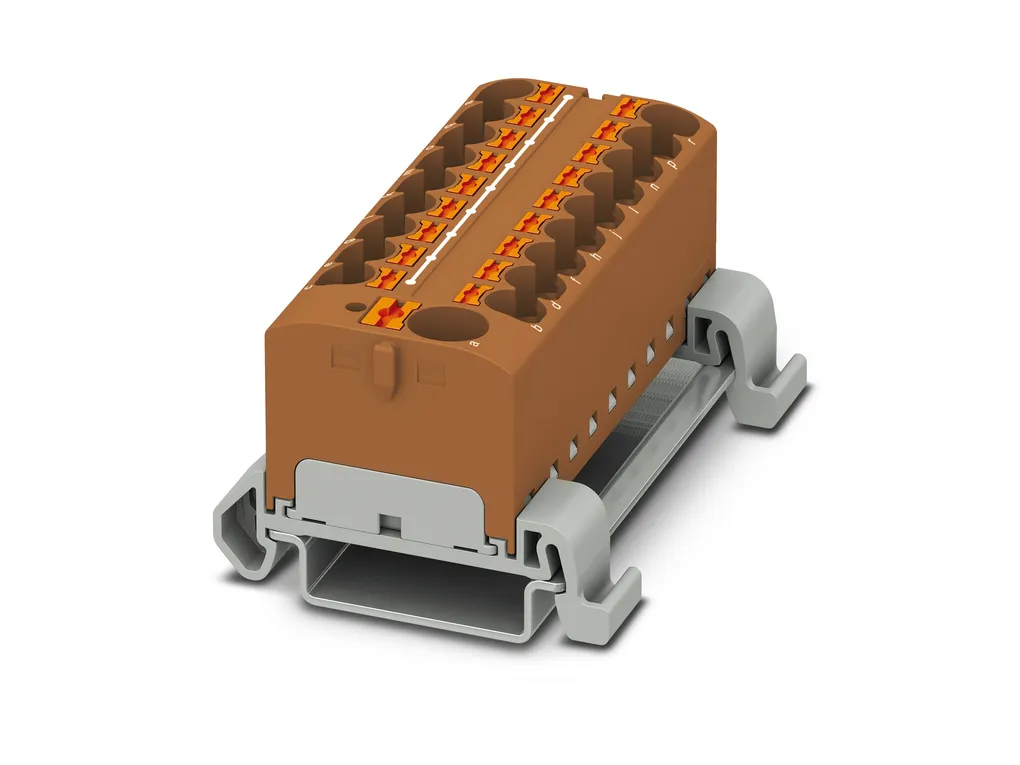

Disponibile PTFIX 6/18X2,5-NS35 GY - Distribution block

Distribution block, Block with vertical alignment and integrated supply, nom. voltage: 690 V, nominal current: 24 A, number of connections: 19, connection method: Push-in connection, Load contact, cross section: 0.14 mm2-4 mm2, Push-in connection, Line contact, Rated cross section: 6 mm2, cross section: 0.5 mm2-10 mm2, mounting type: NS 35/7,5, NS35/15, color: gray

Cod. Articolo: 3273110

Cod. Fornitore: 3273110

PHOENIX CONTACT